THERMOFUSION

A state-of-the-art roll making process

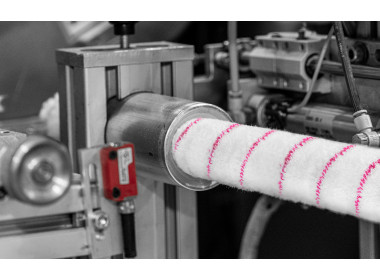

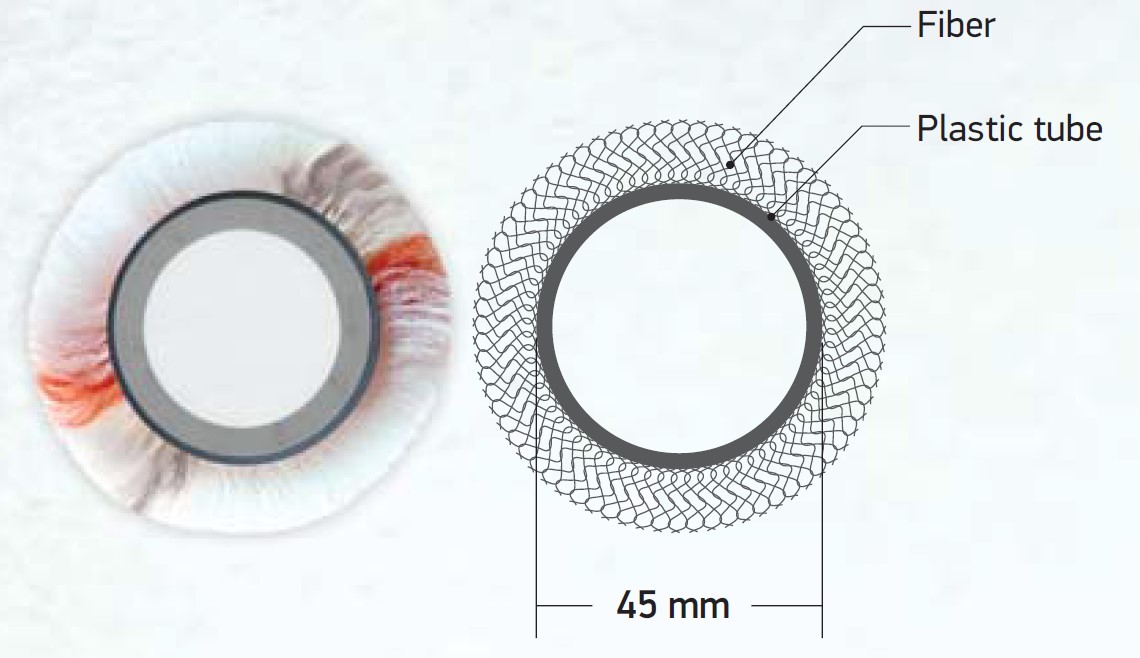

Thermofusion - a method of spiraling textile materials onto a plastic tube with the help of heat, without the use of adhesives, thus providing greater coverage power per m², longer use and resistance to all known solvents.

For sewn rollers, the polyurethane inside the sewn roller is also bonded to a plastic tube by a thermo-fusion system, which guarantees a significantly longer life than the conventional adhesive bonding method.

WHAT MAKES A GOOD PAINT ROLLER?

See HERE how is made our best-selling roller.

WHAT'S THE DIFFERENCE BETWEEN ROLLERS?

MANUFACTURING - thermofusion and sewn

MATERIAL - polyester, polyacrylic, polyamide, microfiber, wool

LENGTH - from 6 mm to 23 mm, the longer thread leaves a more striking texture

WEIGHT DENSITY - is defined by the weight per m² and goes from 440 g / m² to 1,200 g / m²

WAY OF WEAVING - woven and knitted

BEOROL IS THE LEADING MANUFACTURER OF PAINT ROLLERS ON THE SOUTHEASTERN EUROPE MARKET

During our business we have developed two types of production:

Thermofusion rollers

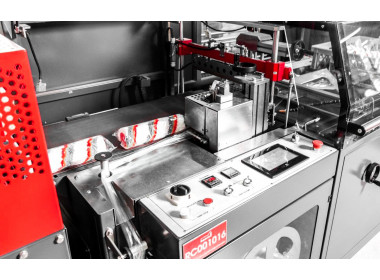

Upgraded process of thermofusion is Beorol’s contribution to the tools market. It combines a plastic tube and the fabric into a whole, using heat and mechanical pressure. That way you get the main part of the paint roller, so called body. Plugs are inserted in the paint roller body and they are connected with the wheel barrel which contains the fuse. Through the wheel barrel and fuse runs the wire of the paint roller handle and thus a full paint roller ready for painting is obtained.

Thermofused paint rollers are designed for treating flat surfaces of different materials with different paints and varnishes, depending on the type and characteristics of fabric. Depending on the size of the area to be treated, it is necessary to choose the appropriate dimension of the paint roller. In our range we have thermofused paint rollers of the following lengths 7, 9, 10, 18, 23, 25 and 50cm.

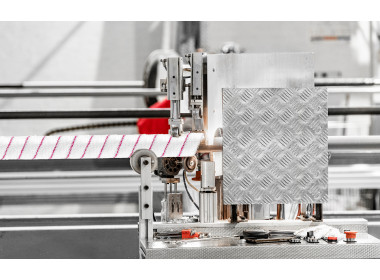

Sewn rollers

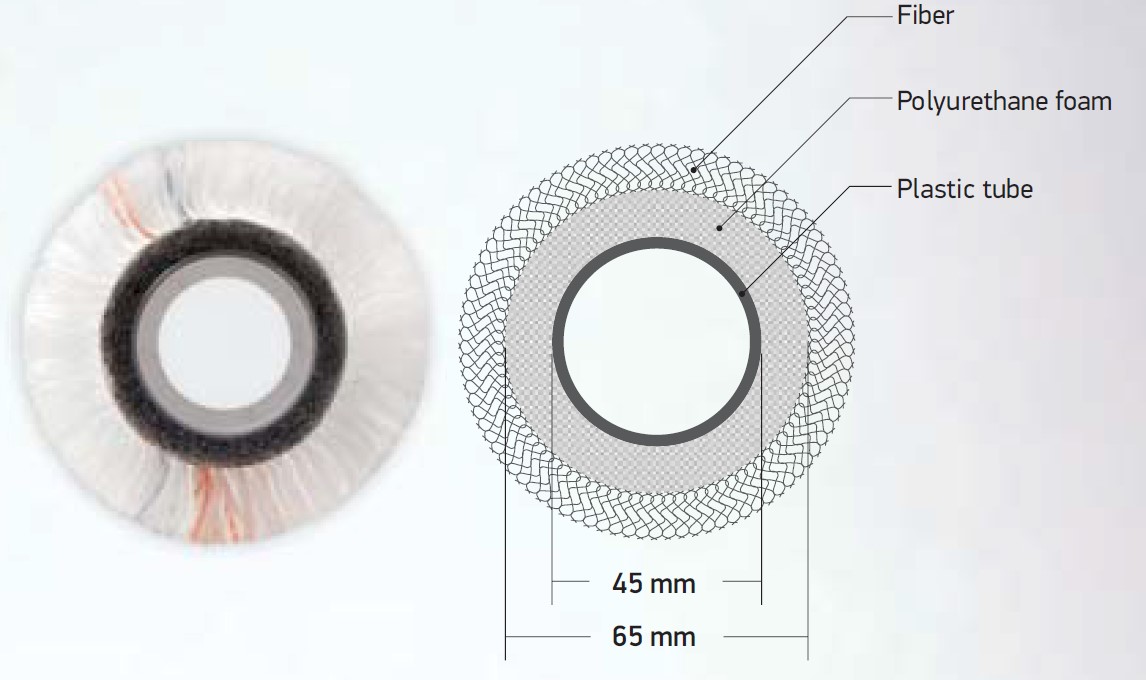

Produced by combining process of thermofusion and sewing. Plastic pipe and polyurethane foam are connected in a whole, so we get a supporting structure with the increased surface elasticity. On the resulting tube we pull sutured and turned over fabric. By pulling we get a strong connection between the polyurethane foam and sutured fabric.

Due to the mutual elastic forces it comes to the straightening of the stitch, so its unrecognizable on the sewn paint roller. Polyurethane foam inside the paint roller does not absorb the paint, so there can not be remains of it aft er washing the paint roller.

Polyurethane foam inside the paint roller does not absorb the paint, so there can be no remains of it aft er washing the paint roller. Sewn paint rollers are designed for rough building surfaces, mainly semidispersion, dispersion and facade paints. Depending on the size of the area to be treated, it is necessary to choose the appropriate dimension of the paint roller. In our range we have sewn paint rollers of the following lengths 18, 23, 25 and 27cm.

PRODUCTION CAPACITY

1000

SEWN ROLLERS

4000

THERMOFUSION ROLLERS

6000

SMALL PAINT ROLLERS

5000

NUMBER OF PALLET PLACES

.jpg)